## MicroFactory Unveils "Dog Crate-Sized" Robotic Factory Capable of Human-Level Dexterity **News Title:** Dog crate-sized robot factory trains itself by watching human demos **Report Provider:** Interesting Engineering **Author:** Prabhat Ranjan Mishra **Published Date:** September 17, 2025 This news report details the development of a revolutionary robotic system by San Francisco-based company MicroFactory. The system, housed within a compact box, features two robotic arms designed to replicate human hand dexterity and perform a wide range of precision tasks. ### Key Findings and Capabilities: * **General-Purpose Robotic System:** MicroFactory has developed a general-purpose tabletop robot that can perform tasks typically done by humans with their hands. * **Precision Task Performance:** The robotic arms are capable of intricate tasks such as circuit board assembly, component soldering, and cable routing. * **Versatile Gripper:** The system's gripper can be easily swapped with tools like a soldering iron or screwdriver, enhancing its versatility. * **Self-Training Mechanism:** The robot can be trained through two primary methods: * **AI Training:** Leveraging artificial intelligence. * **Human Demonstration:** Users can physically guide external robotic arms to demonstrate tasks, which the in-box arms then replicate. * **Task Replication:** The in-box robotic arms can perfectly copy demonstrated actions, such as grabbing and placing objects. * **UI for Task Breakdown:** A user interface is provided to break down complex tasks into smaller, manageable steps. * **Efficiency and Speed:** The system is designed to automate repetitive manual work and assemble objects faster and with greater precision than traditional methods. * **Demonstrated Capabilities:** The company has showcased the robot's ability to: * Assemble small electronic motherboards perfectly. * Remove protective layers from adhesive tape. * Assemble real products. * Thread a needle perfectly, demonstrating fine motor control. * **Non-Humanoid Design Philosophy:** MicroFactory's co-founder and CEO, Igor Kulakov, emphasizes that general-purpose robots do not need to be humanoid. Their design focuses on simplicity and ease of implementation in both hardware and AI by avoiding human-like form factors. * **Effectiveness Claim:** The general-purpose robot is claimed to be more effective than a humanoid robot. ### Company and Development Timeline: * **Company:** MicroFactory * **Founders:** Igor Kulakov and Viktor Petrenko * **Launch Year:** 2024 * **Prototype Development Time:** Approximately five months. ### Market Reception and Future Outlook: * **Preorders:** MicroFactory has received hundreds of preorders from customers interested in various applications. * **Applications:** Potential uses include assembling electronics and even processing snails for escargot. * **Cost-Effectiveness:** The robotic arms are highlighted as being able to learn new tasks faster and deliver small electronic assembly services at a low cost. ### Notable Quotes: * Igor Kulakov, co-founder and CEO of MicroFactory: "General purpose robots are good, but it’s not necessary [to] be humanoid. We decided to design robots from scratch that will still be general purpose but not in human shape, and this way, it can be done much simpler, much easier, in hardware and on the AI side." The report suggests a significant advancement in robotics, offering a compact, versatile, and trainable solution for automating precision tasks with a focus on efficiency and cost-effectiveness.

Dog crate-sized robot factory trains itself by watching human demos

Read original at Interesting Engineering →The system can do almost all of the things that humans can do with their hands. A San Francisco-based company has developed a robotic system that is installed in a small box. The innovation includes two robotic arms capable of grabbing and moving objects. The system is capable of performing precision tasks like circuit board assembly, component soldering, and cable routing.

Developed by MicroFactory, the general-purpose tabletop robot can be trained with the help of AI or human demonstration. Robotic system can assemble objects faster The system is designed to automate repetitive manual work. The robotic system can assemble objects faster with precision. The innovation’s gripper can be swapped with a soldering iron or screwdriver.

The manufacturer claims that the system can do almost everything humans can do with their hands. The company has shown that the robotic system can assemble small electronic motherboards perfectly. MicroFactory highlighted that to set up the system, users must use copies of these robotic arms from outside the box.

Robotic arms can perform multiple tasks Using another external robotic arm, users will show the in-box AI system how to perform a task. They can show how to grab an object and place it in a different place. The original in-box robotic arms will copy the action and be able to perform the same tasks perfectly.

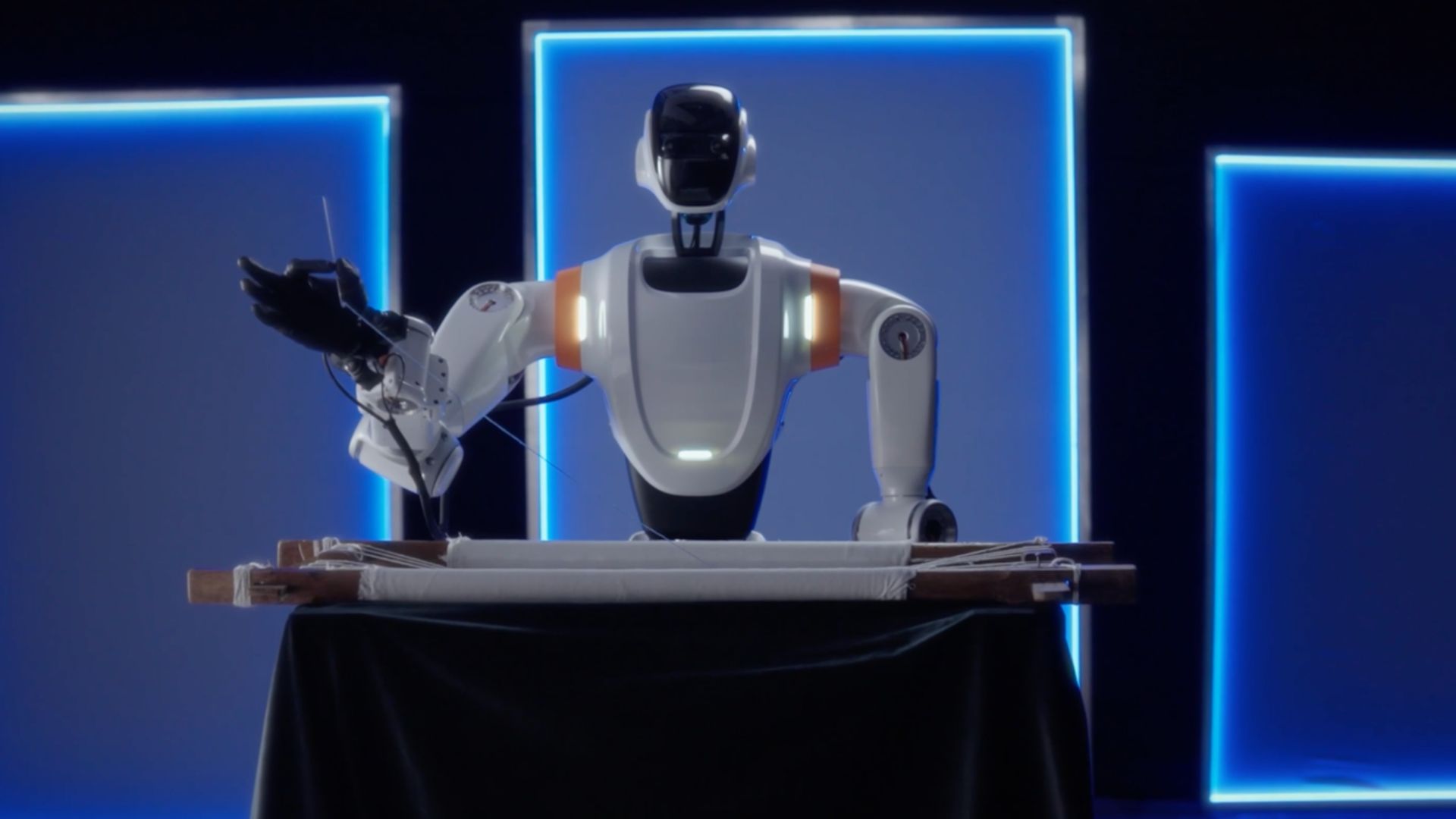

The company also made a UI that breaks down tasks into small steps. “General purpose robots are good, but it’s not necessary [to] be humanoid,” said Igor Kulakov, the co-founder and CEO of MicroFactory, in an interview with TechCrunch. “We decided to design robots from scratch that will still be general purpose but not in human shape, and this way, it can be done much simpler, much easier, in hardware and on the AI side.

” The system can also remove the protective layer from adhesive tape. A robot can also assemble real products. The general-purpose robot is claimed to be more effective than a humanoid. It can thread a needle perfectly Igor Kulakov and Viktor Petrenko launched MicroFactory in 2024. It took them about five months to build their prototype.

Now the company has hundreds of preorders from customers looking to use the machines for various applications, including assembling electronics and even processing snails to be shipped to France for escargot, reported Tech Crunch.RECOMMENDED ARTICLES In a video posted on X, the robotic arms are seen threading a needle perfectly.

The two arms are seen performing tasks in perfect sync. Both arms are capable of holding small objects and placing tiny objects on them accurately. The company also pointed out that the system can be trained by physically guiding the arms through complex motions. The robotic arms can learn new tasks faster and deliver small electronic assembly services at a low cost.

ABOUT THE AUTHORPrabhat Ranjan Mishra Prabhat, an alumnus of the Indian Institute of Mass Communication, is a tech and defense journalist. While he enjoys writing on modern weapons and emerging tech, he has also reported on global politics and business. He has been previously associated with well-known media houses, including the International Business Times (Singapore Edition) and ANI.