## Icarus Raises $6.1 Million for Space Logistics Robots **News Title:** Icarus raises $6.1M to use robots to supplement space labor **Report Provider:** The Robot Report **Author:** Brianna Wessling **Publication Date:** September 18, 2025 **Time Period Covered:** Current developments and future plans, with a target launch in early 2027. ### Executive Summary Icarus Robotics, a New York-based startup, has secured **$6.1 million in seed funding** to develop and deploy free-flying robots designed to perform logistics tasks on the International Space Station (ISS). The funding round, led by Soma Capital and Xtal with participation from Nebular and Massive Tech Ventures, aims to address the high cost and scarcity of labor in space by automating mundane tasks. This will allow astronauts to dedicate more time to scientific experiments and research. Icarus plans to launch its first robot to the ISS in **early 2027**, in collaboration with Voyager Technologies Inc. ### Key Findings and Conclusions * **Addressing Space Labor Shortages:** Icarus is tackling the significant challenge of labor scarcity and high costs in space, where it is estimated to cost **$130,000 per hour** to sustain a human presence. * **Automating Logistics Tasks:** The company's primary focus is on automating common logistics tasks such as unpacking cargo, resupplying bags, and performing routine maintenance like seal inspections and filter changes. These tasks currently consume a substantial amount of astronaut time. Anecdotal evidence suggests that astronauts might spend up to **1 hour and 30 minutes** of their time searching for tools within cargo bags before commencing an experiment. * **Free-Flying Dexterous Robot:** Icarus's initial product will be a free-flying robot featuring two robotic arms and sensors, engineered for operation in a zero-gravity environment. * **Building Robust AI for Space:** A major hurdle for Icarus is developing robust Artificial Intelligence (AI) systems that can function effectively in space, where data for training large models is extremely limited. * **Phased Approach to Autonomy:** The company plans to begin with semi-autonomous teleoperated robots and gradually transition towards fully autonomous systems. * **Simulated and Real-World Data Training:** Icarus is utilizing physics simulators with zero-gravity support for robot training and intends to collect real-world data through teleoperation once its robots are in space. This data is crucial for bridging the "sim-to-real gap" and creating specialized models for microgravity manipulation. * **Practical and Revenue-Generating Solution:** Icarus emphasizes that its robotic solutions are practical and can be revenue-generating by enhancing the efficiency of space stations and freeing up astronauts for higher-value scientific work. ### Key Statistics and Metrics * **Seed Funding Raised:** $6.1 million * **Cost of Keeping a Person Alive in Space:** $130,000 per hour * **Time Spent on Finding Tools in Cargo (Anecdotal):** Up to 1 hour and 30 minutes out of 2 hours dedicated to an experiment. * **Cargo Arrival on ISS:** Up to three and a half tons of cargo can arrive, requiring weeks for unpacking. * **Planned ISS Launch Date:** Early 2027 ### Important Recommendations (Implied by Company Strategy) * **Prioritize Data Collection in Space:** This is essential for developing effective AI models for space operations. * **Leverage Existing Infrastructure:** Partnering with companies like Voyager Technologies Inc. is crucial for gaining access to the ISS. * **Balance Automation with Astronaut Well-being:** Recognize that certain tasks, such as watering plants, contribute positively to astronaut mental health and should be preserved. ### Significant Trends or Changes * **Growing Investment in Space Robotics:** The funding secured by Icarus signifies a rising trend of investment in robotics for space applications. * **Focus on Space Logistics:** Companies are increasingly recognizing the necessity of automating logistical challenges in space as human presence and activities expand. * **Advancements in AI for Extreme Environments:** The development of AI capable of operating in challenging environments like microgravity is a key area of innovation. ### Notable Risks or Concerns * **Space Flight Delays:** As with any space mission, the planned 2027 launch is subject to potential delays. * **Sim-to-Real Gap in Robotics:** Bridging the gap between simulated training and real-world performance, particularly in a zero-gravity environment, remains a significant technical challenge. * **Data Scarcity for AI Training:** The limited availability of robotics data in space is a fundamental barrier to developing advanced AI. ### Material Financial Data * **Seed Funding:** $6.1 million * **Lead Investors:** Soma Capital and Xtal * **Other Investors:** Nebular and Massive Tech Ventures ### Company and Personnel Information * **Company:** Icarus Robotics * **Founders:** * **Ethan Barajas (CEO):** Possesses experience at NASA, including work on lunar rovers, and studied at Caltech. * **Jamie Palmer (CTO):** Brings robotics expertise from Columbia University's ROAM Lab and high-performance engineering experience from the Mercedes-AMG Petronas Formula One Team. * **Location:** New York-based startup. * **Partnership for ISS Deployment:** Voyager Technologies Inc. ### Future Plans * **First Zero-Gravity Test Flight:** Planned for the upcoming year. * **ISS Deployment:** Targeted for early 2027. * **Discrete Testing:** Ongoing testing will be conducted prior to the space launch.

Icarus raises $6.1M to use robots to supplement space labor - The Robot Report

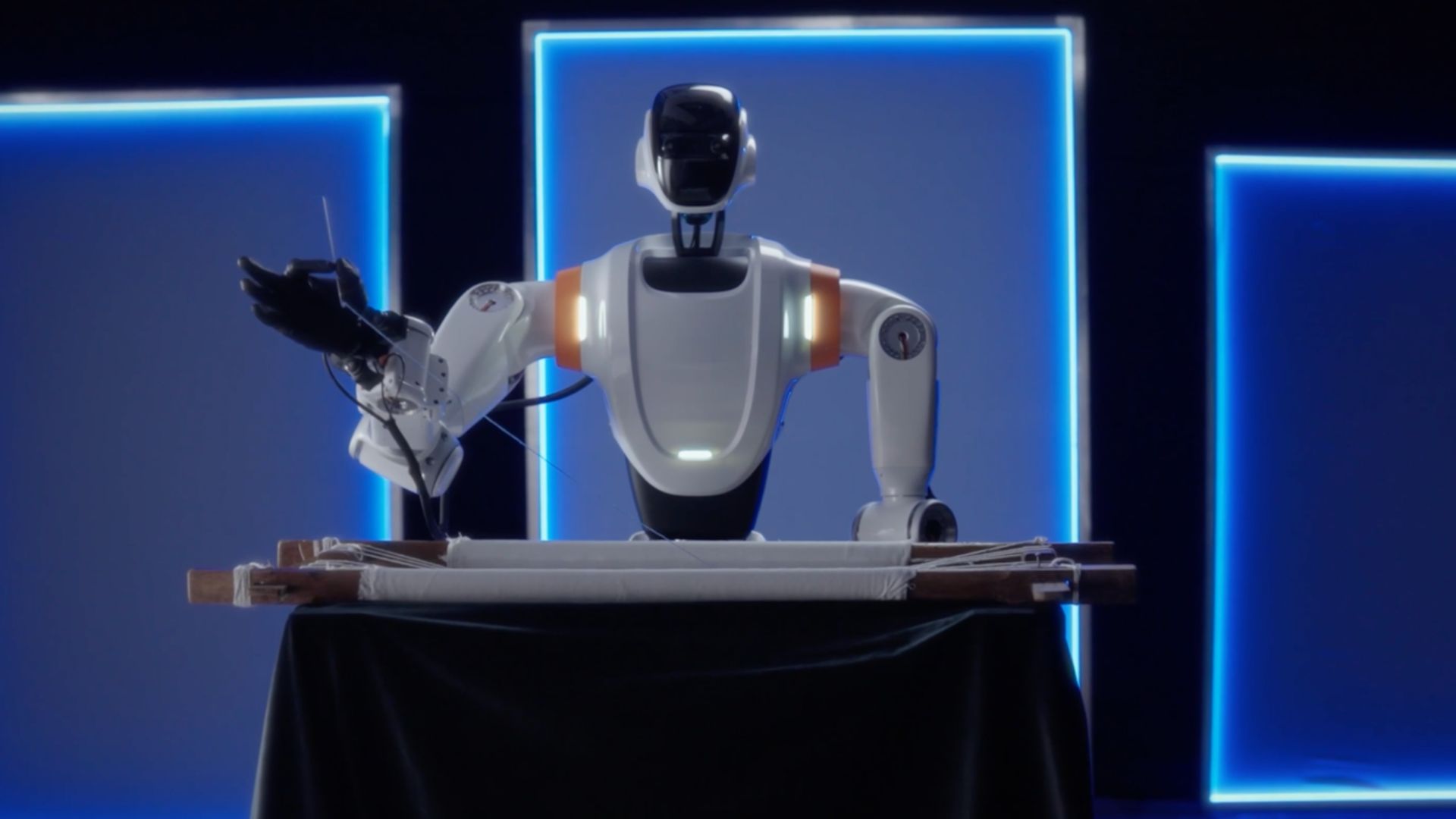

Read original at The Robot Report →Icarus is initially creating a free-flying robot with arms that can perform logistics tasks on the ISS. | Source: Icarus Many robotics companies are trying to solve logistical problems and labor shortages, while also building robust artificial intelligence and hardware to handle a variety of tasks. Icarus Robotics trying to do all of those things in space, where labor is more scarce and expensive than anywhere on Earth.

The New York-based startup yesterday announced that it has raised $6.1 million in seed funding. Soma Capital and Xtal led the round, which also included participation from Nebular and Massive Tech Ventures, among others. Icarus’ founders, CEO Ethan Barajas and Chief Technology Officer Jamie Palmer bring a variety of robotics and space technology experience to the table.

Barajas began his career at NASA at just 17 and has since worked on lunar rovers while studying at Caltech. Palmer has robotics expertise from Columbia University’s Robotic Manipulation and Mobility (ROAM) Lab and high-performance engineering experience from the Mercedes-AMG Petronas Formula One Team.

“Half of the Earth’s GDP comes from labor,” Barajas told The Robot Report. “And if we take the Earth as a model, labor is going to be so important as we move from low Earth orbit to the moon and Mars, and that labor has to be robotic. Barajas knew from working at NASA that it is difficult to get crew time to actually perform experiments on the International Space Station (ISS).

It costs $130,000 an hour just to keep a person alive in space, he said, and much of an astronaut’s time is spent sleeping, working out, and doing other necessary activities to stay happy and healthy. “The little bit of time that they do get in their day, they get to spend on experiments in manufacturing.

And out of that little bit of time, there are all of these things like seal inspection and filter changes,” Barajas said. “The biggest, which is a huge time sink, is cargo and bag resupply.” Common logistics tasks in space need automating From left to right, Ethan Barajas, CEO, and Jamie Palmer, CTO, the co-founders of Icarus.

| Source: Icarus Robotics According to Barajas, three and a half tons of cargo can arrive on the ISS, and astronauts spend weeks unpacking these bags. “We found out, from going upstream and downstream and talking to these commercial ops planners, and even astronauts themselves, that, anecdotally, if they were to spend two hours on an experiment, the first hour and 30 minutes would just be finding the tools in those cargo bags to actually carry that experiment out,” Barajas said.

He noted that the tasks Icarus is targeting are tasks that we’ve already automated in warehouses here on Earth. “One thing we never realized is that you could totally automate away most of these little tasks that astronauts spend their time on, but some of it’s actually really therapeutic,” Barajas said.

“People hate unpacking cargo; this is one thing that is just not enjoyable and takes so much time. But something that we found is that astronauts really love watering plants and things like that, and that’s very helpful to their mental health. So that’s been interesting to actually find and learn from these astronauts that have been on the ISS.

” “The first product we’re pushing is a free-flying, dexterous robot,” Palmer said. “So, if you can imagine, almost like an ROV or drone, it has a free-floating base with two robotic arms out in front, and then sensors basically looking down on the workspace.” Zero-gravity environments pose a challenge for AI Icarus plans to start with semi-autonomous teleoperated robots, to build towards fully autonomous systems.

| Source: Icarus One of the biggest challenges facing Icarus Robotics is creating a robust AI system that can work in space. There is not a lot of robotics data that can be used to build large models for tasks on Earth. In space, even less data is available. “The hardest part about building these large models — and it’s a similar problem to what we’re seeing in terrestrial robotics — is the lack of data that exists for robots,” Palmer said.

“In order to [gather this data], one of the things that we have to do to really start collecting distribution data is to get to space first. It’s probably the biggest barrier to entry for any robotics company.” Once the Icarus team is in space, it plans to teleoperate robots to collect data at first, with the eventual goal of building fully autonomous models, Palmer said.

In the meantime, the company is using simulated data to train its robots as much as possible before sending them into space. “A lot of the physics simulators that are currently available on the market actually have support for setting the physics to zero G,” Palmer said. “But like all robotics, you have to bridge the sim-to-real gap.

That’s when our getting to space becomes so important, because while we’re teleoperating, we can collect these human examples.” “We can scale the human expertise with the robotic fleet, and then ultimately, what that allows us to do is make these bespoke models that are going to be specific for microgravity manipulation,” he continued.

Icarus prepares for a 2027 launch Right now, Icarus Robotics is working with Voyager Technologies Inc., one of the only companies with a commercial airlock on the ISS, to bring its robots into space in early 2027. Of course, as with any space flight, this could be subject to delays as we get closer to launch, noted Barajas.

In the new year, the team also plans to conduct its first zero-gravity test flight. “This funding is going to get us to that space deployment, that’s what everything is working towards,” Barajas said. “In the meantime, there’s obviously some discrete testing that we need to get done before we can launch in space.

” While space robotics might seem like a far-off goal, Barajas and Palmer asserted that they’re trying to solve very practical problems. “It’s one of the only environments where the cost of the robot and the operator is actually less than the thing that you’re replacing,” Barajas said. “So, the teleoperation actually still is revenue-generating for these stations, and [it] gives them more time back than they would be spending if your astronauts were wasting their time on some of these menial tasks.

” “We want to be a workforce multiplier to these astronauts while they’re on station. We want them to be doing the important science, not checking the filters out,” he continued.